WARNING: This product can expose you to chemicals that are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information, visit www.P65warnings.ca.gov.

WARNING: This product can expose you to chemicals that are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information, visit www.P65warnings.ca.gov.The APR Turbocharger Inlet System uses a massive 4" carbon fiber inlet tube that attaches to the factory airbox, or upcoming APR Intake System. Attached to the carbon fiber tube is a massive 4" cast aluminum inlet which is organically shaped to retain the largest possible cross sectional area within the pipe all the way to the inlet of the turbocharger's compressor cover. Despite the visually odd shape, keeping the cross-sectional area as large as possible is the key to the pipe's performance gains, and greatly outflows smooth looking continuously tapering designs.

Interlocking adapter rings form a port-matched ideal entrance to the turbocharger, while larger rings (sold separately) provide port-matched support for even larger hybrid turbocharger upgrades. A thick stainless steel heatshield protects the pipe from the hot turbocharger manifold, and an external stainless PCV pipe provides proper PCV placement without impacting the inlet's design.

PLEASE NOTE: Does not fit ROW vehicles with Right Hand Drive

System Overview

The Restriction

Turbo Inlet Pipe Turbo Inlet Pipe Turbo Inlet Pipe Turbo Inlet Pipe Turbo Inlet Pipe Turbo Inlet Pipe Turbo Inlet Pipe

The factory cast inlet pipe is small. It has a maximum internal diameter of 2.8, at the widest point, and is internally restricted as illustrated in the photos. This pipe is only capable of achieving a maximum of 490 CFM at 28 of H2O when tested alone. Attaching any intake system to this pipe will only result in a lower flow rate, and when using the factory back pipe, airbox, filter and inlet scoop, airflow drops below 430 CFM.

The APR Solution

Our cast inlet pipe is huge and on its own it achieves a staggering 710 CFM with the stock turbocharger adaptor! This is a 45% improvement over the factory part. When paired with APRs upcoming intake system, airflow only drops to 690 CFM, a 60% improvement over the entire stock intake system! When attached to the factory airbox, filter and frontal scoop, airflow drops to 575 CFM, which is 34% better than the stock system and 17% better than the stock inlet by itself with an ideal entrance. This further clarifies the point that no intake can outperform the APR turbo inlet if the factory turbo inlet is left intact.

APRs engineers tested a multitude of other turbocharger inlet designs in pursuit of more flow and power. It was quickly determined the part could not act as an upgrade on its own because of the significant increase in diameter required. The rear inlet pipe also had to be upgraded to utilize this larger diameter. Other designs, which may look smoother, and offer a continuously reducing taper, are extremely limited. At 3.5, 550 CFM is achievable. At 4 560 is achievable. In contrast, our system achieves 710 CFM under the same test. Given how restrictive these other designs are, upgrading to our system, while still using the factory airbox, filter and frontal scoop, will outflow any intake system!

Optional Intake Filter System

The APR Turbocharger Inlet System outflows the factory components by up to 45%, and jumps to 60% when adding the APR Intake Filter.

Adding the optional APR Intake Filter to the APR Turbocharger Inlet System completely transforms the system from subtle to extreme. Our massive 9 long cotton filter with frontal opening connects to a 6 carbon fiber inlet tube that gradually necks down to the 4 back tube. You will hear every ounce of the 5-cylinder turbocharger systems massive demand for airflow, and youll do so at a 60% CFM improvement over stock! This was only possible with an open filter system as the airflow demands called for an unboxed design. Simply put, this is the best intake system on the market for satisfying uncompromisingly demanding airflow requirements.

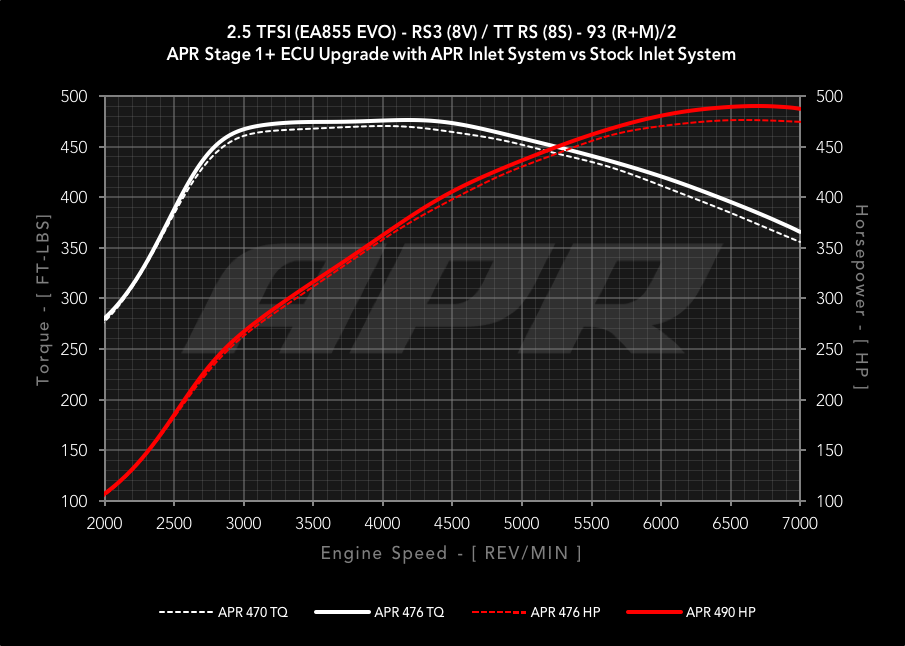

Dyno Testing

Further Information

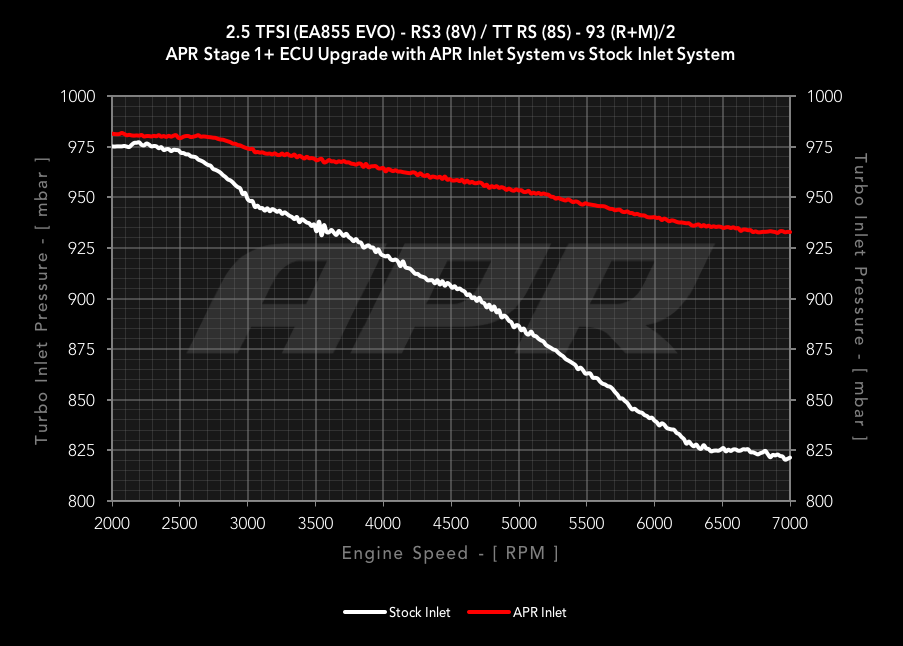

APRs Engineers fully instrumented the engine with pressure sensors and thermocouples (fast response temperature sensors) to further illustrate the affects this product has on the system as a whole. In the simplest terms, this upgrade allows the turbocharger to operate at a lower pressure ratio, which means it will operate more efficiently. It reduces the restriction on the inlet of the turbocharger, allowing the inlet to see closer to ambient pressure conditions. This directly translates to lower pre-turbine backpressure (EMAP), lower turbocharger shaft speed, lower turbocharger compressor discharge temperature, and for the ability to achieve higher boost pressure levels.

The following data was collected with ambient conditions sitting around 985 mbar, 29.4C with 66% relative humidity. The vehicle was setup as Stage 1 (93) with stock hardware, vs Stage 1+ (93) with the APR Inlet. The depression at the inlet decreased by 112 mbar, emap decreased 360 mbar, compressor discharge temperature dropped 14c and the engine was able to achieve 106 mbar more boost pressure by redline. This directly translated to more horsepower and torque, while everything ran cooler and more efficiently.

- PDP tag:

- Free Shipping*

- Sales:

- On Sale

- PDP tag:

- On Sale