WARNING: This product can expose you to chemicals that are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information, visit www.P65warnings.ca.gov.

WARNING: This product can expose you to chemicals that are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information, visit www.P65warnings.ca.gov.The APR K04 Turbocharger System features many upgrades over the 2.0T's factory equipped IHI turbocharger, making it an excellent upgrade. The integrated turbofold design features a cast stainless steel exhaust manifold and turbine housing, integrated into one single unit. This design aids in turbocharger spool while the stainless steel construction is capable of withstanding higher exhaust gas temperature for longer periods of time than lesser materials, such as cast iron. The CNC-machined, billet aluminum compressor wheel and higher flow exhaust turbine wheel expand the turbo's efficiency range, allowing for higher output across a wider RPM range.

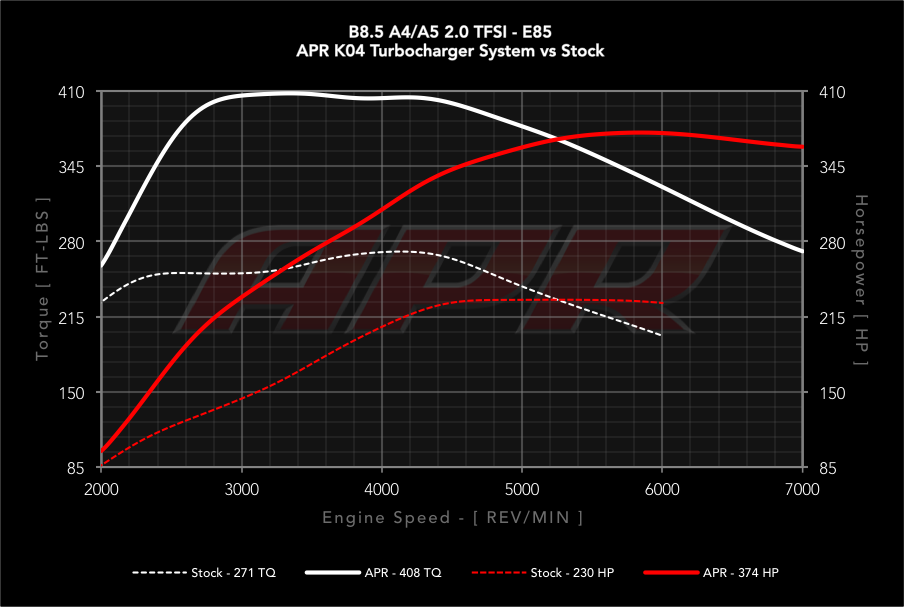

Using 93-octane fuel, the APR K04 Turbocharger System produces an astonishing 344 horsepower and 369 ft-lbs of torque. Unlike the factory turbocharger, power stays strong and doesn't dramatically taper towards the vehicle's new 7,100 RPM redline. Ethanol 'flex fuel' compatible engine variants can take advantage of automatic E85 map blending to acheive up to 374 horsepower and 408 ft-lbs of torque simply by filling the tank! APR's calibration experts have safely maximized the full power potential of the turbocharger unit, while keeping reliability at the forefront of their calibration strategies.

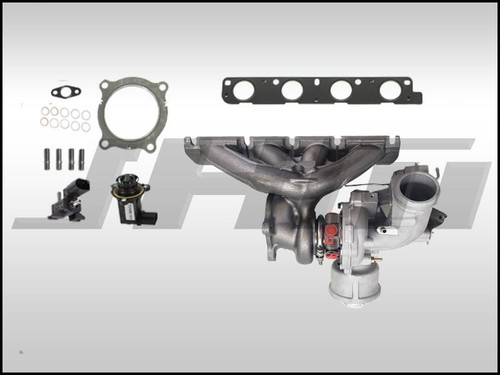

APR K04 Turbocharger System Components

Turbocharger

At the heart of the K04 Turbocharger System is an APR proprietary customized version of the factory Borg Warner K04-64 turbocharger originally equipped on VAGs high-output models, such as the Golf R and S3. The turbocharger features a CNC-machined, billet compressor wheel and stainless steel exhaust turbofold.

Each turbocharger unit is machined, assembled and clocked in house at APR with the necessary brackets to ensure proper wastegate fitment and orientation. Each wastegate is then calibrated for precise operation and control to ensure seamless integration with the expertly recalibrated OEM engine management system.

Integrated DV

One of the greatest benefits to the APR K04 turbocharger system is its simple, yet elegant design. APR's CNC-machined OEM compressor cover with integrated DV recirculation mount significantly reduces engine bay clutter and saves the end user from the hidden costs of purchasing extra throttle body pipes, hoses, clamps and DV mounts for recirculating boost pressure. The compact design also removes extra charge piping volume to allow for faster boost response and less locations for boost leaks. Furthermore, charge air pressure is directed directly at the compressor wheel which helps keep the turbo spooled upon lifting the throttle, minimizing turbo lag.

Engine Management

The factory Bosch MED 17 engine management system is responsible for proper operation of the engine during constantly changing environmental and load conditions. With built in compensational data for environmental variables and varying load conditions, the factory ECU is far more complex and intelligent than units found in other vehicle makes and marques.

With the significant amount of changes included in the APR K04 Turbocharger System, APRs Engineers spent months calibrating the engine management system, including hundreds of hours of in-house chassis dyno development. Drivability, gear changes, cruising and part throttle operation were tuned to operate smoothly as if intended by the OEM through proper torque management. APRs Electrical Engineers built new coding functions, strategies and routines into the ECU to control conditions normally unseen at factory power levels. Thanks to APRs incredible proprietary calibration suite, data logging software and full access to the coding structure of the ECU, appropriate and intelligent changes are made to ensure flawless drivability and excellent performance without compromise.

Engine Calibration:

APRs Calibration Engineers restructured the engines volumetric efficiency (VE) model to correctly determine the ECUs calculated load and deliver proper torque management. Thanks to APRs patented boost control coding, the ECU is able to perform closed loop boost control well beyond relatively low limits dictated by the factory structure. This directly translates to safer and more predictable operation while additionally producing more power and torque across the entire power band.

Additionally, through the properly reconstructed VE model, accurate open loop fueling is achieved, translating to insignificant fuel trim adjustments. Closed loop fueling is calibrated to control lambda perfectly under all operating conditions. Furthermore, compensations, such as ones related to intake air temperature, exhaust temperature, and altitude, are adjusted to handle the larger variances compared to the factory, low-output setup.

APRs Calibration Engineers have optimized cam timing, runner flaps, valve lift, ignition timing, engine load and lambda to provide tremendous leaps in power while retaining the OEM knock control strategy. Ethanol 'flex fuel' compatible engine variants can take advantage of automatic E85 map blending to add power simply by filling the tank. The result is safely achieved power, optimized for various fuel grades found around the world from low-quality pump fuel, all the way to high-quality, oxygenated race fuels.

Compressor Surge Avoidance:

To aid in turbocharger reliability and longevity, APRs engineers carefully studied the turbochargers compressor maps to avoid regions where compressor surge may be experienced. The K04 turbocharger has fantastic response characteristics and is able to produce incredibly high pressure at low airflow levels, but in doing so, the turbocharger runs into issues of compressor surge. In the area between 3000-4000 RPM, APRs Calibration Experts have elected to limit boost pressure.

Torque Management and Traction Control:

Torque management plays a big role in how the vehicle feels and performs, especially during moments of low gear, rapid acceleration. Since APRs torque management system relies on the engine managements phenomenal torque reporting abilities, it is able to adjust to every environmental situation it encounters. To achieve a targeted torque level, the ECU applies the appropriate changes to mass airflow and ignition.

Acceleration Enhancements:

Through further calibration changes APRs Calibration Engineers were able to increase the acceleration rate of the vehicle. Ignition delays are reduced resulting in a more responsive pedal without altering overall throttle sensitivity and resolution. Drivability was greatly improved by reducing the throttle lag commonly noticed at slow speeds and while reapplying throttle after decelerating. APRs Motorsport Rev Limiter allows power to climb all the way to redline without dropping off several hundreds of RPM earlier. Lastly, APRs tried and tested Motorsport Launch Limiter allows the driver to focus on launching the vehicle, rather than controlling the engine speed.

Part-Throttle Drivability:

Beyond wide-open throttle performance, APRs Calibration Engineers spent countless hours optimizing vehicle drivability under daily, part-throttle, driving. The vehicle fully retains its impressive daily driver status and simply has more power on tap should the driver request more with his or her right foot!

APR EMCS and APR Mobile:

APRs EMCS program-switching technology and APR Mobile put control of the ECU in the operator's hand to access modes for standard pump fuel, high-output race fuel and even reduced-output valet modes to protect the vehicle against improper use by other individuals. This technology is patented by APR and is found nowhere else in the world. Its Performance Without Compromise only APR can deliver!

Gaskets

APR doesnt cut corners even with the most mundane details of the kit. Every nut, bolt, stud, washer, clamp, and gasket necessary for the install is included with the kit.

Dyno Testing

Horsepower and torque were measured in APRs in-house, Soundmaster dyno cell, using a Dynapack all-wheel dynamometer. Multiple stock and modified runs were conducted and the SAEJ1349 corrected results were averaged together to represent the differences between a stock and APR K04 2.0T. Crank power figures were estimated based on VAGs factory advertised results.

| Stock As Rated by VAG | Stock 93 AKI As Measured by APR | 91 AKI 95 RON | 93 AKI 98 RON | 100 AKI 104 RON | 104 AKI 108 RON | E85 | |

|---|---|---|---|---|---|---|---|

| - E85 only supported on flex fuel supported models. These models have a silver metal intake manifold. | |||||||

| - Max rev limit TCU controlled on automatic transmissions. | |||||||

| - APR recommends and tuned with Sunoco GT 260 for 100 AKI mode and Sunoco GT 260 Plus for 104 AKI mode. Never use lower octane than specified by the mode. | |||||||

| - Max increases are based on APR's actual measured stock values and not those reported by VW. | RON = ROW Fuel Grades | AKI = North American (RON+MON)/2 Fuel Grades. | |||||||

| - Reported wheel figures measured on APR's in house Dynapack Dynamometer with a US Spec B8.5 A4 Allroad Tiptronic with an APR K04 turbocharger system, APR Intake, APR Race DP and APR Intercooler, using SAEJ1349 correction and an average of multiple runs. Crank figures estimated based on the measured wheel figures. Results will vary depending upon environmental conditions, vehicle, transmission, vehicle health, operating conditions, temperatures, fuel grade, dyno type, dyno setup, and other modifications. | |||||||

| Speed Limiter | Limited | Limited | Unlimited | Unlimited | Unlimited | Unlimited | Unlimited |

| Peak Horsepower (HP) | 174-217 HP | 230 HP | 329 HP | 344 HP | 355 HP | 361 HP | 374 HP |

| Peak Torque (FT-LBS) | 236-258 TQ | 271 TQ | 350 TQ | 369 TQ | 385 TQ | 405 TQ | 408 TQ |

| Max Horsepower Gain over Stock (HP @ RPM) | +113 HP @ 7,000 RPM | +122 HP @ 7,000 RPM | +139 HP @ 7,000 RPM | +142 HP @ 7,000 RPM | +155 HP @ 7,000 RPM | ||

| Max Peak Torque Gain over Stock (FT-LBS @ RPM) | +92 TQ @ 5,300 RPM | +108 TQ @ 5,350 RPM | +119 TQ @ 5,100 RPM | +148 TQ @ 3,200 RPM | +154 TQ @ 3,100 RPM | ||

Requirements and Recommendations

- Intake System

APR's software is designed to utilize the factory mass airflow (MAF) sensor and housing. The APR Carbon Fiber Intake System is recommended and required to meet the advertised power output. - Exhaust System

A full high flow Race DP is required. The factory DP after the catalyst pipe must be replaced as the factory chambered resonator design is too restrictive. - Intercooler System

APR an upgraded intercooler system is required to meet the advertised power figures. APR does not recommend use of this kit with the factory intercooler as it's too ineffective. - Transmission

The APR K04 Turbocharger System greatly increases torque over the factory output levels and as such, an upgraded clutch may be necessary to transmit power to the ground. APR highly recommends upgrading the factory clutch to one that suits the operator's intended driving style. - Spark Plugs

APR's software is designed for use with NGK BKR8EIX spark plugs gapped to 0.024" 0.002" or 0.6mm 0.05mm with a change interval of 10-15,000 mi or 16-24,000 km.

- PDP tag:

- Free Shipping*

- Sales:

- On Sale

- PDP tag:

- On Sale